Industrial heating for the modern age

Discover the new state-of-the art in dielectric heating for industrial processes.

High efficiency dielectric heating

Dielectric heating, commonly known as microwave, radio frequency or high frequency heating, is a process that involves generating heat within a material by subjecting it to an alternating electromagnetic field. As the dipolar molecules within the material rapidly align themselves to the alternating electric field, their oscillations lead to friction, which generates uniform heating throughout the entire cross-section of the material.

Dielectric heating is an incredibly efficient way to apply heat for industrial processes such as drying, curing, welding, forming and the chemical transformation of materials.

From Analog to Solid State

Here's an analogy...

Dielectric heating is the principle on which your domestic microwave oven works. Using that analogy, SolidWatts designs and builds the system to create and deliver the microwaves. We then sell that ‘power source’ to companies that integrate it into their ‘oven’ product. Of course, we are building far more sophisticated systems, orders of magnitude more powerful, fully optimised for industrial processes. And our customers are too.

Microwave and RF heat can be applied to a wide range of materials, as long as that material has a dipolar element.

Legacy limitations

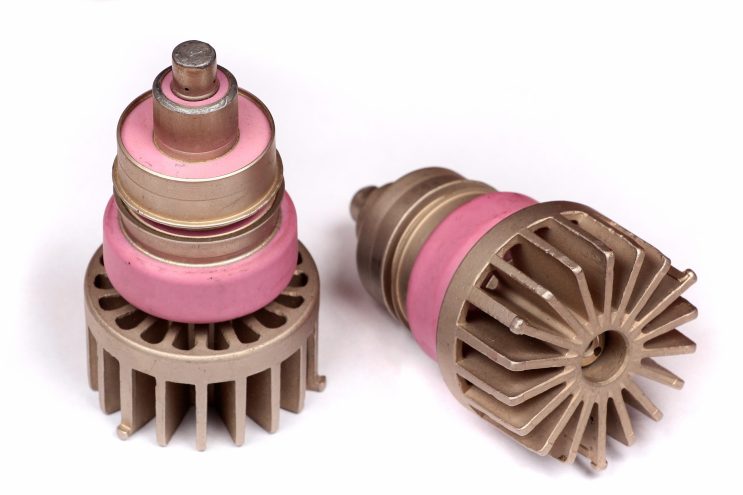

For decades, niche industrial applications have been addressed with dielectric heating based on vacuum tube technology. However, this ageing technology has multiple drawbacks:

- Limited power (<100 kW typically)

- Short lifespan requiring frequent tube replacement

- High voltage safety and maintenance considerations

- Difficult to match the power to the application and to fine-tune process control

- Large installation footprint

- Fewer suppliers and rising prices as vacuum tubes become redundant ‘old’ technology

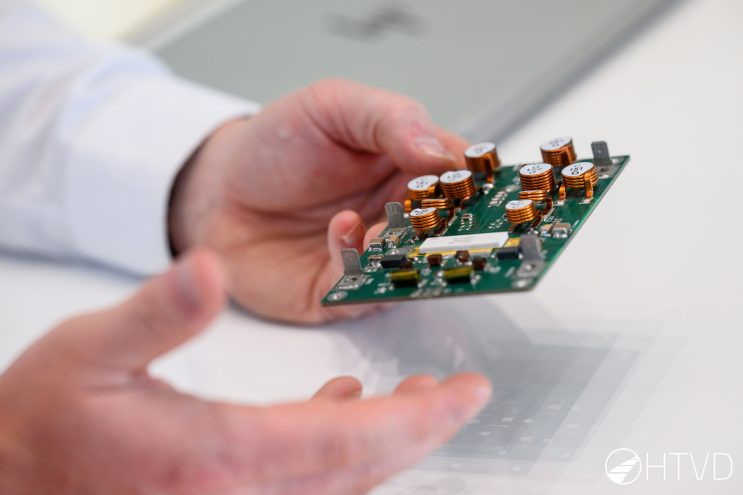

Leveraging the latest solid-state transistor technology, SolidWatts brings industrial process heating into the 21st century.

We've created a step-change from the current state-of-the-art with tube amplifiers, including:

- Full digital process control for matching and controlling power, frequency and phase to the application and material(s) to be heated enabling new and better processes

- Virtually unlimited power, scalable from 10 kW to Megawatt levels, disrupting high power gas fired processes

- >85% energy efficiency, twice as good as vacuum tubes

- Service lifetimes, 5 to 10 times better than a vacuum tube

- Easier, safer operation and maintenance (no high-voltage, radiation)

The business impacts

Great technology is one thing. But it needs to improve the bottom line. Here’s how.

- Digital process control ensures quality production processes with high throughput and few defects whilst facilitating process innovation and improvement

- High power unlocks many new applications where RF heating has not previously been viable

- High energy efficiency reduces energy usage, carbon emissions and OPEX

- Long service lifetimes increase productivity, whilst also reducing maintenance costs

- Faster, lower cost installation with enhanced personnel safety

- Smaller footprint provides more design options and easier integration

- Reducing energy expenditure cuts costs

- Electrification reduces emissions

Niche applications have been addressed with radio frequency dielectric heating based on vacuum tube technology. However, this has multiple drawbacks:

- Unlimited power from 10 kW to Megawatt levels

- >85% power efficiency (XX better than tube amplifiers)

- 10x longer service life

- Small footprint

- Regular 3 phase power supply and no radiation concerns

Leveraging the latest solid-state transistor technology, SolidWatts brings industrial process heating to the 21st century.

Creating a step-change from the current state-of-the-art with tube amplifiers, our advantages include:

- Virtually unlimited power, from 10 kW to Megawatt levels

- >85% energy efficiency, twice as good as vacuum tubes

- Service lifetimes, 5 to 10 times better

- Easier, safer operation and maintenance (no high-voltage, radiation)

- Full digital process control for matching and controlling power, frequency and phase to the application and material(s) to be heated

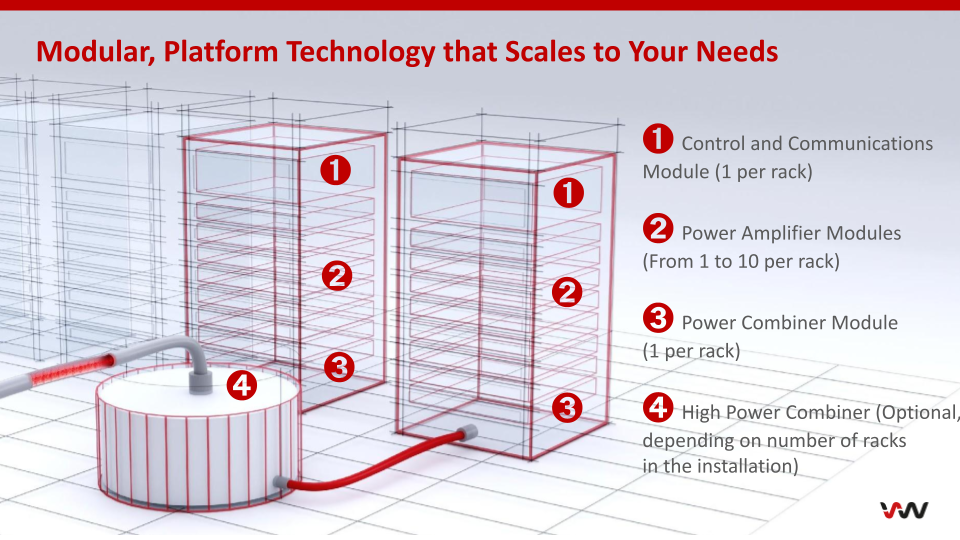

Architecture

Our architecture is unique

Platform technology that is modular and scalable. According to client needs:

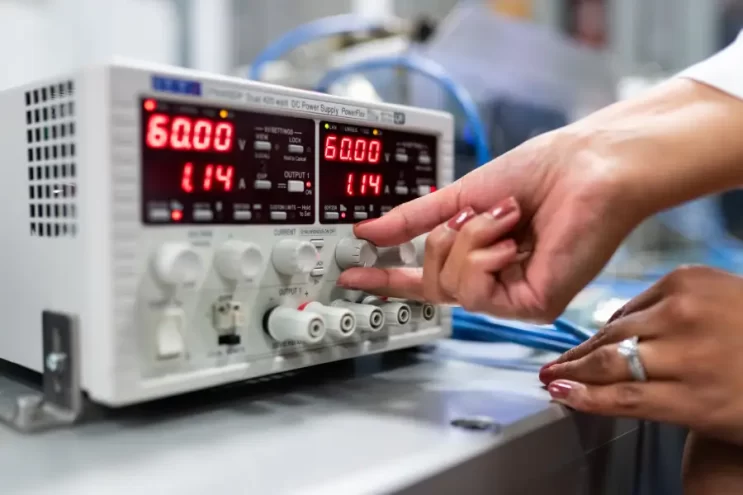

- One or more 27.12 MHz 10 kW power modules can be stacked in 19 inch racks

- A common control and communications module controls all the amps in its stack

- Multiple stacks can be combined to reach Megawatt power levels

- The power from multiple power modules or stacks is ‘combined’ in a power combiner of our unique design…

- …before being applied to the final application through our application matching network

Why design matters...

- Off-the-shelf solutions (rather than expensive custom designed solutions) are faster to deploy and lower cost to buy

- Standard modules provide redundancy and fast change-out of modules. This creates high reliability and availability

- Standard modules can easily be added (or removed) for fast and easy scalability. Easily adapt the solution as your needs change